OEM & ODM

INTOR doesn’t just manufacture.

We think together, and we grow together.

Professional OEM & ODM

PARTNERSHIP

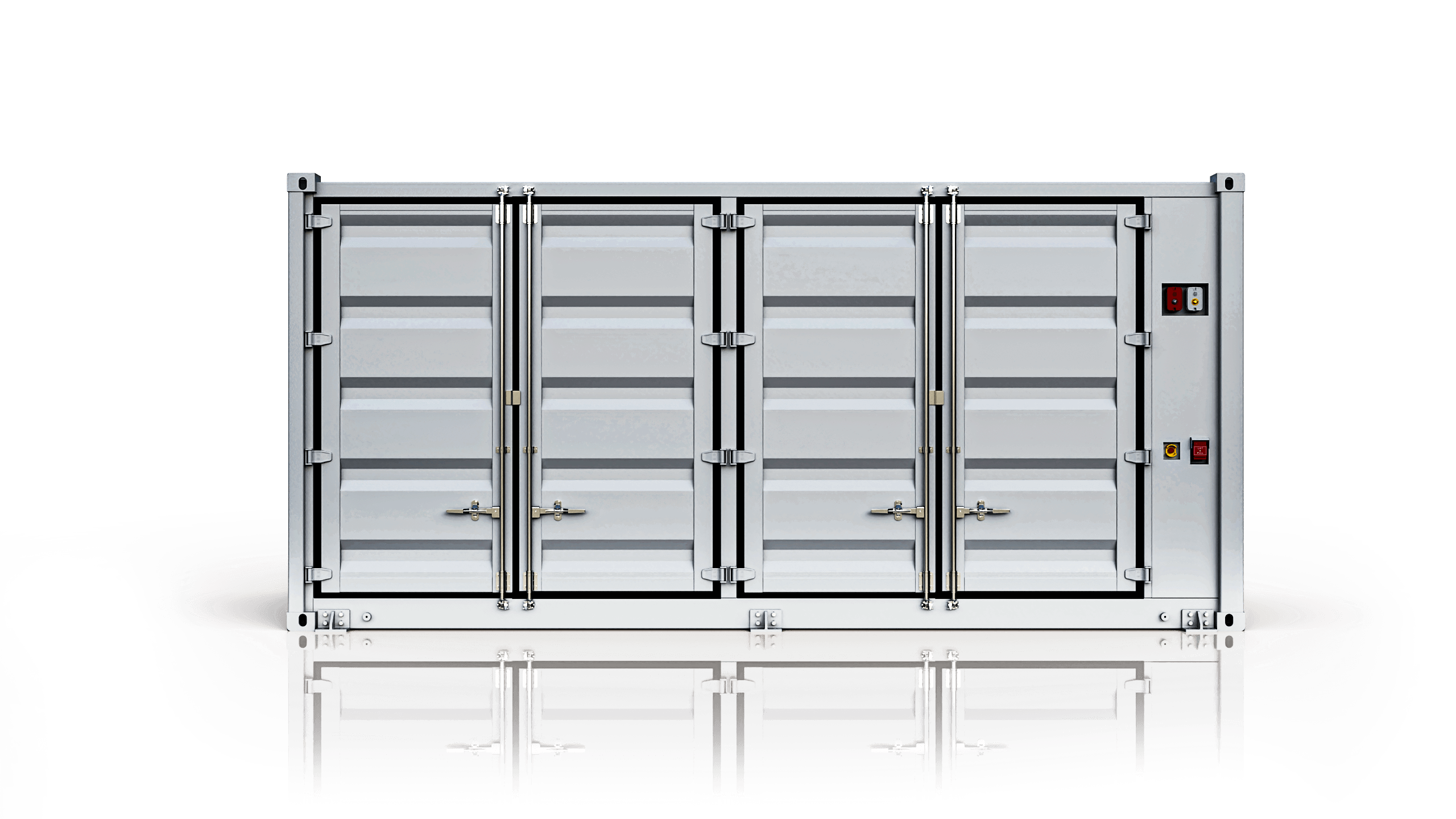

Providing customer-tailored ODM/OEM solutions seamlessly connected with global clients

OEM

As an OEM partner, we produce finished goods strictly according to customer-provided designs and trademarks, combining our manufacturing expertise with competitive quality and cost.

ODM

Building on INTOR’s technological capabilities, we provide comprehensive product development services covering the entire process from product planning and development to production and quality control.

With accumulated know-how, we deliver finished products with optimal functionality and top quality at a reasonable price.

Professional ODM Process

SIGNATURE SOLUTION

INTOR independently carries out the entire process from product planning to fluid

analysis, structural analysis, and electrical systems design implementing

technology-driven ODM designs to deliver safe and efficient energy storage systems.

ODM Process

BR (Business Request)

- Receive development requests based on customer requirements and verify technical and business needs

- Review development feasibility through internal evaluation procedures and obtain management approval

- Establish a Cross-Functional Team composed of experts in electrical systems design, structural analysis, quality, production, and other fields

- Define detailed plans for the entire development process, including schedules, role assignments, and review/approval procedures

ODM Process

DV (Design & Development)

- Create designs that ensure the electrical safety and mechanical strength of ESS products

- Enhance product completeness through 3D modeling, circuit design, and layout optimization

- Select components and materials with comprehensive consideration for functionality, durability, cost competitiveness, and certification standards

- Securing quality through collaboration with global partners

- Produce prototypes based on design data to verify assembly, functionality, and manufacturability in advance

- Conduct pilot production using collaborative robot–based automated processes

ODM Process

PV (Product Verification)

- Conduct flow and thermal transfer analyses to verify cooling efficiency and HVAC performance

- Evaluate structural stability under various lifting conditions (90° / 45° lifting, snow load, etc.) considering installation and transport environments

- Ensure design reliability and field adaptability through simulations led by the Structural Analysis Team

- Perform external certification tests in accordance with international environmental standards such as RoHS, REACH, and CMRT, as well as customer requirements

- Collaborate with testing agencies and customers for regular quality evaluation and compliance verification

- Obtain final product approval prior to mass production based on certification results

ODM Process

Mass Production

- Based on prototypes and development samples, integrate and analyze all verification results, including customer validation and external certification tests

- Establish quality standards suitable for mass production based on design data, analysis results, and test results

- Apply PPAP and 4M-based quality processes to ensure process reliability.

- Transfer finalized designs to actual production lines after verification

- Implement a connected production system through cooperative clusters and one-stop process lines

- Stabilize mass production through worker training, equipment setup, and the establishment of inspection standards for each process